- Standard and is ususally a 'DIN' type of standard. DIN ISO 2768-mK Where would one get a standards manual explaining these tolerances and their meaning? If anyone can explain this one please by all means do. As stated in the title block: general tolerances DIN ISO 2768-mK DIN EN ISO 13920-BF NN 14 T.1 + 1.2 Thanks in advance.

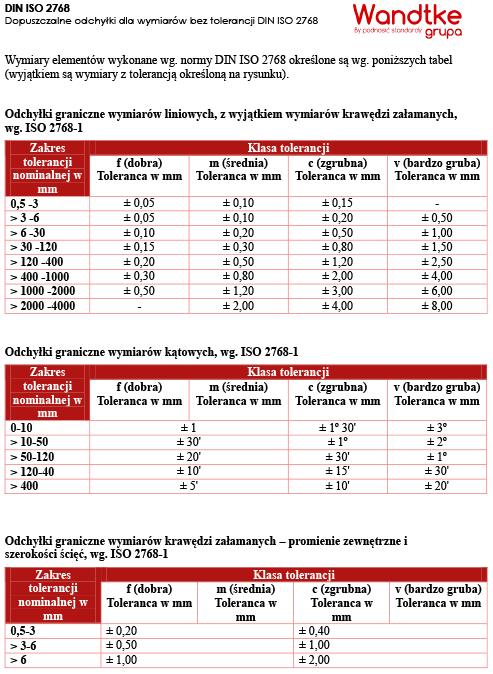

- Dowel Hole Tolerances This part of ISO 2768 is intended to simplify drawing indications and specifies general geometrical tolerances to control those features on the drawing which have no respective individual indication. It specifies general geometrical tolerances in three tolerance classes.

This part of ISO 2768 is intended to simplify drawing indications and specifies general geometrical tolerances to control those features on the drawing which have no respective individual indication. General Product Information - (Show below) - (Hide below).

- Angular Dimension

- External Radius and Chamfer height

- Geometric Tolerance such as straightness, flatness, perpendicularity, symmetry and runout.

We suggest you read this article on go no-go gauges.

General Tolerance : ISO 2768

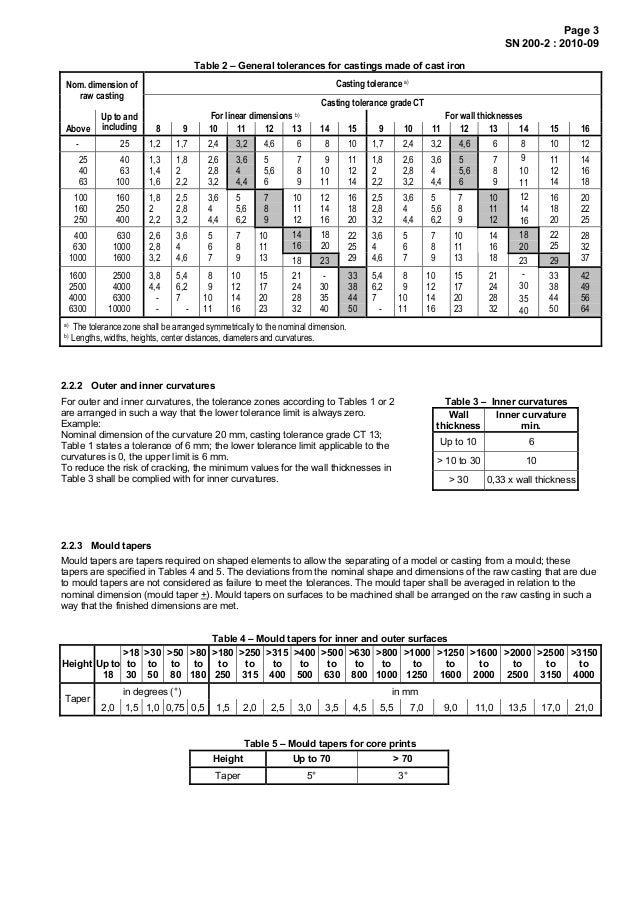

Linear DimensionsNominal Length Range in mmTolerance Classf(fine)m

(Medium)c

(coarse)v

(very coarse)0.5 up to 3±0.05±0.1±0.2-3 up to 6±0.05±0.1±0.3±0.53 up to 30±0.1±0.2±0.5±130 up to 120±0.15±0.3±0.8±1.5120 up to 400±0.2±0.5±1.2±2.5400 up to 1000±0.3±0.8±2.0±4.01000 up to 2000±0.5±1.2±3.0±6.02000 up to 4000-±2.0±4.0±8.0External Radius and Chamfer Heights

Nominal Length Range in mmTolerance Classf

Nominal Length Range in mmTolerance Classf(fine)m

(Medium)c

(coarse)v

(very coarse)0.5 up to 3±0.2±0.2±0.4±0.4over 3 up to 6±0.5±0.5±1.0±1.0over 6±1.0±1.0±2.0±2.0Angular DimensionsNominal Length Range in mmTolerance Classf

(fine)m

(Medium)c

(coarse)v

(very coarse)up to 10±1°±1°±1°30'±3°over 10 up to 50±0°30'±0°30'±1°±2°over 50 up to 120±0°20'±0°20'±0°30'±1°over 120 up to 400±0°10'±0°10'±0°15'±0°30'over 400±0°50'±0°50'±0°10'±0°20'

Din Iso 2768 Mk

Straightness and FlatnessNominal Length Range in mmTolerance ClassHKLup to 100.020.050.1over 10 up to 300.050.10.2over 30 up to 1000.10.20.4over 100 up to 3000.20.40.8over 300 up to 10000.30.61.2over 1000 up to 30000.40.81.6PerpendicularityNominal Length Range in mmTolerance ClassHKLup to 1000.20.40.6over 100 up to 3000.30.61over 300 up to 10000.40.81.5over 1000 up to 30000.50.82SymmetryNominal Length Range in mmTolerance ClassHKLup to 1000.50.60.6over 100 up to 3000.50.61over 300 up to 10000.50.81.5over 1000 up to 30000.512RunoutHKL0.10.20.5Read this article for details on Limit Fit and Tolerance.

Iso 2768-mk Tolerances

ISO 2768-mK and gage size

ISO 2768-mK and gage size

If an outside cylindrical surface (defined on a drawing calling out ISO 2768-mK and DIN 7167) has a diameter of Ø12mm (+0.2 / -0.1) what would the correct “GO” gage size dimension (inside diameter of the gage) to verify this OD requirement?

I would appreciate someone with ISO knowledge to help me getting the right gage size.

I looked up online for DIN 7167 and found some recommendation such as: ”The issuing body recommends using DIN EN ISO 14405-1:2011-04 .”

I did not see DIN 7167 having the envelope requirement by default so, I am little bit confused about the appropriate gage dimension.

Any help will be greatly appreciated.

Thank you